Did you like the article? Share it!

How much does it cost to print labels online?

You may be wondering how much it costs to print adhesive labels for your products today. We are talking about all the elements that can affect the price of the label.

We will give a value to each element so that you can adjust to the purchase of adhesive labels.

If you don't have time to waste, you can instantly get an idea of how many adhesive labels cost for your products by going to our online quotation and ordering system.

Label material

First of all, the material you choose will significantly affect the cost of the label. Keep in mind that there are cards that cost five times more! Let's see some examples together:

- Coated Paper (€): these papers tend to cost little and are an excellent compromise, available in both glossy and matte versions

- Plastic Materials (€): plastics such as adhesive polypropylene are very cheap materials, sought after for their resistance superior to coated papers

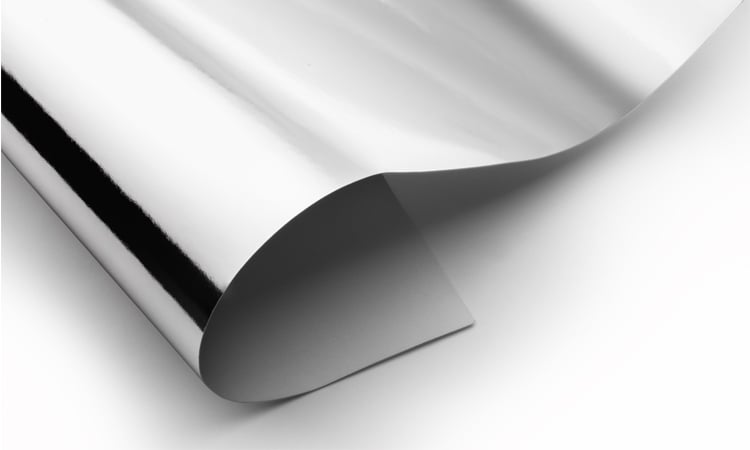

- Metallic papers (€€): silver or gold papers, mirror or satin effect, which allow the printed colours to appear pleasantly metallic and captivating.

- Natural papers (€€): natural papers marked with felt or embossed are sought after by those looking for an extra touch in their product; they cost more but guarantee the product a premium look with little effort.

- Coated Barrier Papers (€€): coated papers based on a plastic barrier, sought after by those who need cold resistance and bucket

- Natural Barrier Papers (€€€): natural papers based on a plastic barrier, sought after by those who need cold resistance and bucket

- Cotton papers (€€€€€): thick papers, ideal for products of the highest level, papers that reach significant prices

- Aluminum (poly laminates) (€€€€€€€): materials composed of various layers of aluminium, labels that require embossing to be printed

With such a wide range of papers, it is easy to get lost; we always recommend initial scrutiny with a packaging expert to choose the ideal and cheapest solution for your product.

Label Size

After choosing the material, our label measurements arrive, the larger our surface area label will be and the more expensive it will be.

When choosing the size of your label, you need to do holistic reasoning, that is, to go and see the size of our product container, the amount of information we have to give to the customer, our logo and the various images we want to show.

The size of your label must also be taken into account with the Type of paper; papers of specific thicknesses (from natural upwards) must not be too small as their rigidity risks not allowing correct labelling.

Quantity and Type of print

Another essential cost that affects the printing of our adhesive labels is start-up printing, which is the procedure that will affect the cost of labels with a fixed value, regardless of whether we print 50 or 100,000.

However, this cost is differently amortized by different types of printing; if not on request, we will suggest which method is most suitable based on the Type of print run to allow the best savings.

Low Quantity of Labels:

- Digital Printing (€)

- Offset printing (€€€)

- Flexo printing (€€€)

High Quantity of Labels:

- Digital Printing (€€€)

- Offset printing (€)

- Flexo print (€)

This is to be taken on a case-by-case basis as the size of the label also binds it; it is necessary to be clear that the more labels are printed of the same type, the more the unit costs per single label will reduce regardless of the type of printing.

It is also advisable to always have an extra margin of labels printed (+ 5-10%) as it is very likely to have waste in labelling.

Processing and finishing for labels

The basis for obtaining the price for the label has already been explained with the previous arguments. Still, if the budget allows you to take an extra step, you can very well think of further embellishing the label with processing and finishing steps.

The main processes will be indicated below with an indicative value of their printing cost indicated:

- Protective varnishing (€): meager cost for an essential element, the flat varnish on the entire label as well as ensuring an increased gloss or opaque effect will allow you to protect the label from scratches.

- Lamination (€€): the lamination of adhesive labels for products consists of the application using glue of a protective plastic sheet (for example, polypropylene) which acts as excellent protection (superior to the protection of a simple paint) and in the support worsens.

-High Build Gloss Varnish (€€€): high build gloss varnish is a process that allows you to obtain glossy effects in relief on some details of the label.

- Hot Foil (€€€€): This process depends on the type of foil, but classic foils such as gold and silver, glossy or matte, have a similar cost. Hot foil is the process of transmitting a metallized foil onto a paper or plastic backing by heat and pressure.

- Hole Removal (€€€€€): Some types of labels may require the removal of some elements inside them, it is always advisable to first ask a label and packaging expert about the feasibility of removing certain holes and elements from your label.

- Contemporary Foil and Embossed (€€€€€): this process differs from simple hot foil simply by the extra cost of a more expensive punch (which only has to be paid once). With this processing, you can highlight some foil elements; this is one of the most beautiful processes that can be done on your label.

Printing facilities

Printing systems are those elements that the printer must produce to print the graphic elements on the label.

The Type and cost vary according to the required printing and the Type of processing.

The most commonly charged systems are:

- Diecut

- Hot foil punch

- Screen printing frame

- Flexo cliché

- Offset plate

Elements such as the die, the punch and the frame are elements that last over time, and therefore generally the printer will only charge them the first time they are requested. Any variation of the element reported by that process (change in size for the die, removal or addition of gold elements for the foil punch, removal or addition of paint elements for the screen printing frame) will require a makeover of the same.

Front labels, back labels, collars ...

Different types of products need various labels; for example, wine bottles tend to have both a front label (to give more value to the brand and the product) and a back label. All the technical and bureaucratic data are entered.

If your label does not have too many extra workings, you could think of printing a single wrapping label that contains all the data; the single label will cost, despite the greater size required, less than having to print two different labels.

If, on the other hand, you are still forced to have a front label and a back label, it is advisable to try to make them the same size and shape, in this way, if they also share the same type of paper, you will save money in the case of simultaneous printing.

Number of References

The number of references indicates the number of subjects that share the same size, shape and paper. This makes the subjects combinable in print together, allowing to avoid extra start-up costs.

For example, you are a company that produces fruit juices, with 80x100mm rectangular labels on matt coated paper. All your labels share these characteristics, and the only difference is the colours and graphics (for example, pear juice, apple juice, orange juice).

Therefore, these three labels will be combined in printing, allowing to avoid extra costs due to printing at different times of these subjects.

Conclusion

The science behind calculating the price of your product label is easier than it seems; I hope I have been thorough in answering your doubts! If you have others, you can contact me directly by email, or if you prefer to continue independently, you can use the online estimator!

Next