Did you like the article? Share it!

Variable Data Printing: study and print file preparation

Bringing personalization to printed products such as labels or flexible packaging is becoming a trend that many well-known brands, start-ups and e-commerce brands are starting to adopt. But how is it possible to customize the labels of your products? The answer is in variable data printing (also known as VDP).

Variable data printing or VDP is a printing method that uses prepress software to modify the output of a digital press to customize each printed label, packaging or flexible packaging with different information from a database. Therefore, it is essential to have a creative idea and a solid database.

This technology allows people to print limited edition numbered labels, different barcode labels, and other images or text without creating a completely new design every time. In short, it is a technology that can offer many opportunities. Indeed, variable data printing is the right choice if you want to create a unique product. Let's see together how it works.

Study and design of the graphic file

Studying a variable data print file is not highly complicated; however, it must be correctly thought out. Before starting, it is necessary to understand how far the variable data printing can go and, therefore, know what elements can be considered "variables" to target the design.

Let's see together what are the elements that can be regarded as variable data within the graphic file:

1. Text: everything that is a font can be considered variable data; numbers, letters, symbols, etc. A text can also have several characteristics, which can be considered variables: the size (body), the colour, the rotation of the text, etc.

2. Colours: we can consider them as variable data since it is associated with any vector and text. All elements of the file may change the colour.

3. Images: any image included in the file, within clipping masks or not, can be added into the database because it can be considered variable data.

4. Barcode / QR code: any type of code may modify; barcodes / QR codes are associated with alphanumeric codes or information such as websites. Here, too, the association takes place via the Excel file.

5. Progressive numbering: a range can be established within which the variable data must work (e.g. from 1 to 10). Knowing all this is very important not to incur nasty surprises once the file preparation is finished. By understanding the elements that may change in printing, we will be able to design the file correctly and create the database necessary for printing.

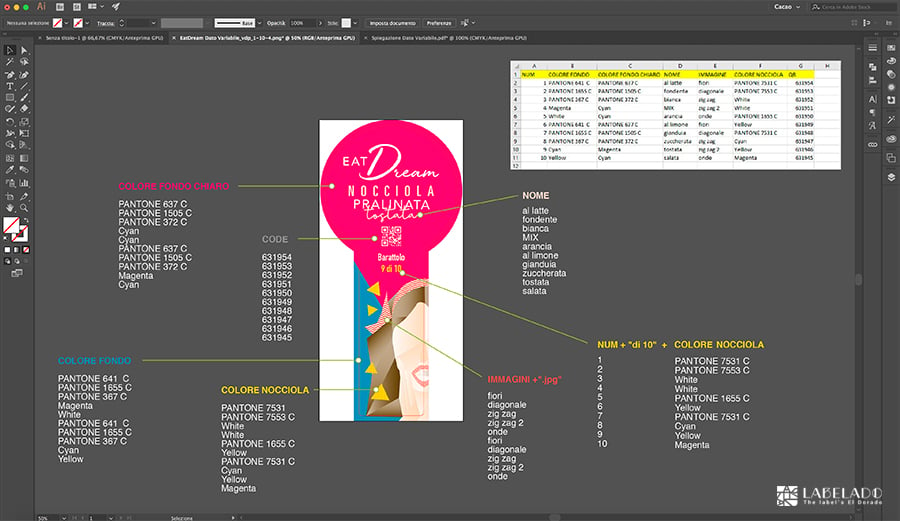

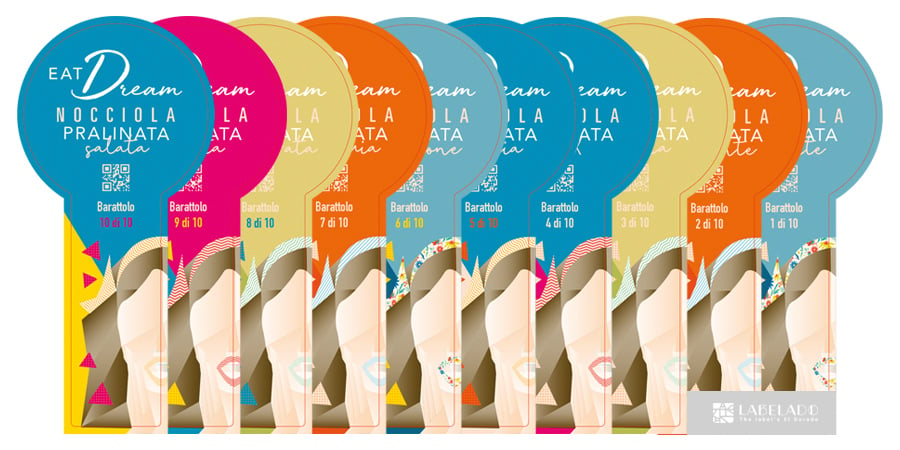

Every single VDP product will turn out to have similarities, but it's different. It is about similarities and reasoned differences; it's up to the designer to plan and preconfigure the file to get the desired result. You should ask yourself a few questions at the design stage: which elements need to stay the same, and which ones do I want to change? Should they vary completely randomly or within certain limits? In the example inserted below, you will see how some elements remain in some way "fixed" and others change entirely at random.

Database preparation

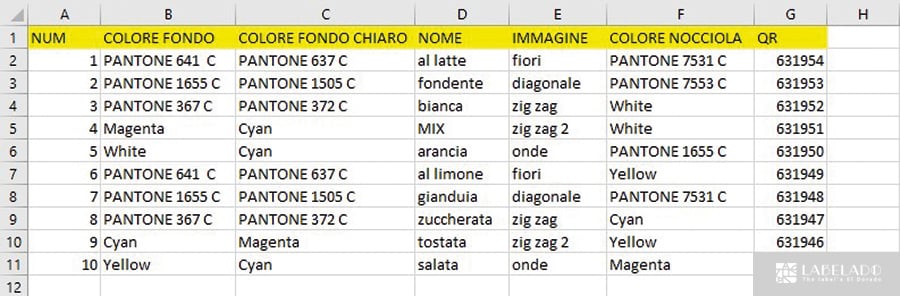

Once the study of the graphic file has been completed, it is necessary to proceed with creating the variable database, which takes place through the use of a data management program, such as Microsoft® Excel®. This file faithfully reports the data of each element that you want to "mark" as a variable. In the Excel® sheet, each column has an element with a placeholder, and each row has a variable. The number of rows used in the sheet determines the number of versions that will be produced. Each column must be named in the same way as the element inserted in the graphic file to create a correspondence; we enter the list of variables in each of them. For more details, see the photos below.

Once finished, the Excel® database must be exported in comma-separated CSV format and is now ready to be imported into the graphic file.

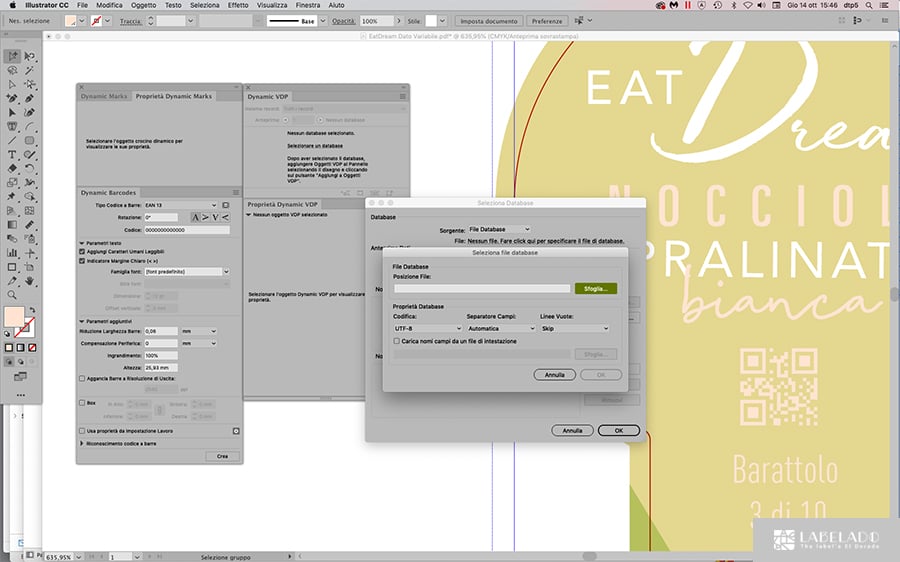

Database Association: VDP Plug-in

The VDP can be treated in different ways; it is usually a plug-in that, if associated with graphic design software such as Adobe® Illustrator®, allows you to create the database association to the various elements of the graphic file.

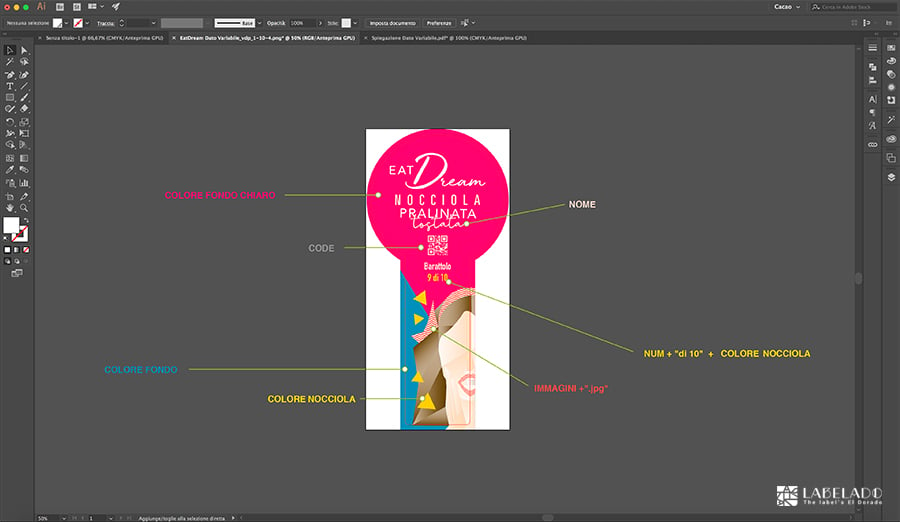

First of all, in the print “model” file, all elements of our design that we have meant as variables must be defined and “marked” with a placeholder. Now, it is necessary to associate the variable database to the graphic file. Thanks to the software, through the association, more or less automatically, the elements marked with the placeholder will be filled with the variable components of the database.

At this point of the process, the plug-in begins to "calculate" the variables, allowing you to see a preview of the results and browse the various versions obtained from the database association.

This crucial step is tricky since every single typo will block the flow of computation and reveal problems. I'll explain. We are still talking about computers, you know, they do not miss anything. For this reason, it is essential to pay attention to how, for example, the colours are named in the database; if there is no correspondence within the graphic file, the process of the association will hang.

Once this sweaty step has been completed, we just have to expand the work to create the variable instances to print. The PDF file will then be sent to a digital printing system, which depends on the type of machine and workflow system you have, and therefore we will not deal with it.

Illustrated Step of the print file preparing process

Let's now see an illustrated example of the preparation of a file made by us.

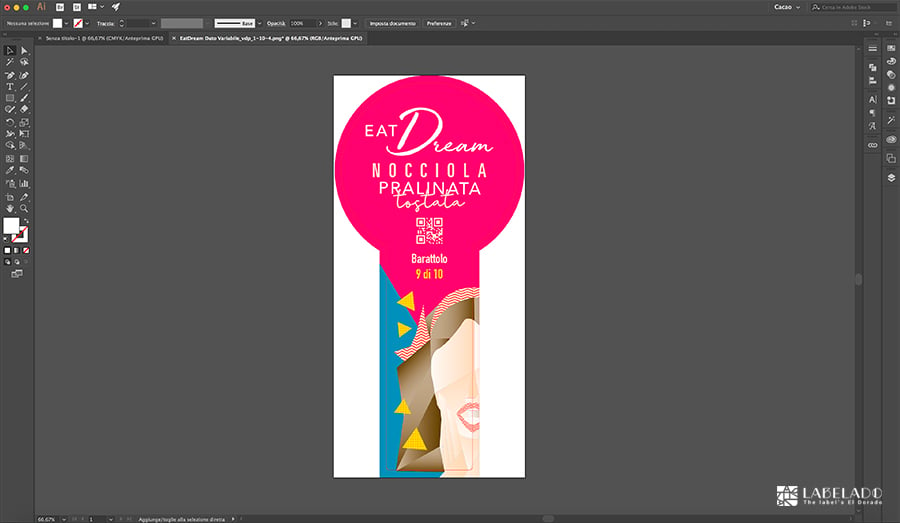

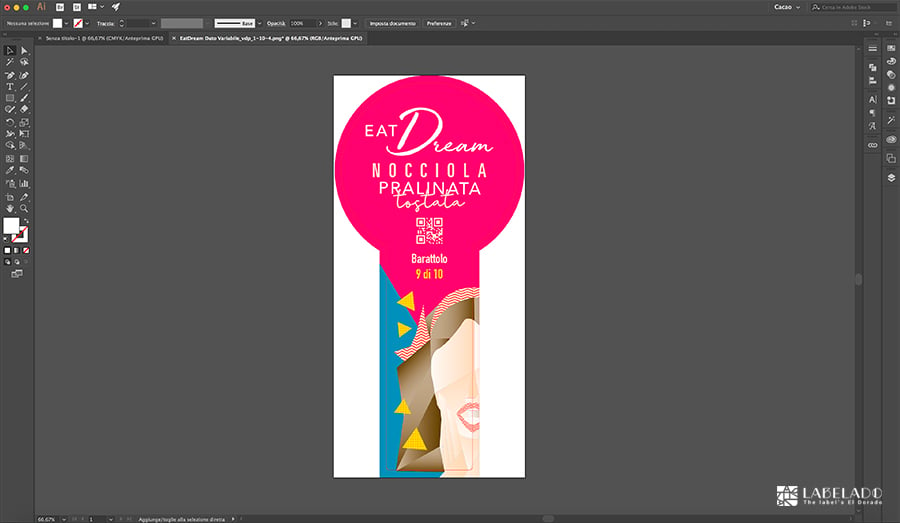

Step 1. Study and design of graphics (already aimed at managing variable elements.

ì

Step 2. Definition of variable elements: texts, colors, images, alphanumeric codes, barcode, QR code, progressive numbering.

Step 3. Variable database creation using data management program (Microsoft® Excel®) + Database export in CSV format - separated by commas.

Step 4. VDP Plug-in Opening (Dynamic VDP in Adobe® Illustrator®)

Step 5. Filling variable fields with database elements. Explanatory example to understand association mechanism.

Step 6. Expanding the job to create variable instances to print. + Send the PDF file to a digital printing system.

Which products can be printed with the VDP?

Variable data printing can be used to print different types of products, from the simplest such as business cards, envelopes, letters with different headings, names, contacts and addresses, or simple stickers with various barcodes, lottery tickets, badges and passes, to the most complex from a graphic point of view such as stickers, covers, flyers, letters, leaflets, etc.

A special mention goes to the use of VDP in the world of packaging and adhesive labels. Here it becomes a powerful tool since it allows you to create variable data with one click, making thousands of unique examples in each version, with many colours and designs, like in a work of art. What can be achieved turns out to be a helpful packaging solution for limited or numbered editions capable of engaging the public.

As you can see from this article, creativity will come to life through variable data printing. Now that you know precisely how variable data works, it's time to express yourself.

If you want to know more or are interested in creating a label using the variable data technique, fill in this form with your questions and a member of the Labelado staff will answer as soon as possible.

Next