Did you like the article? Share it!

What is trapping and why is it important for your file?

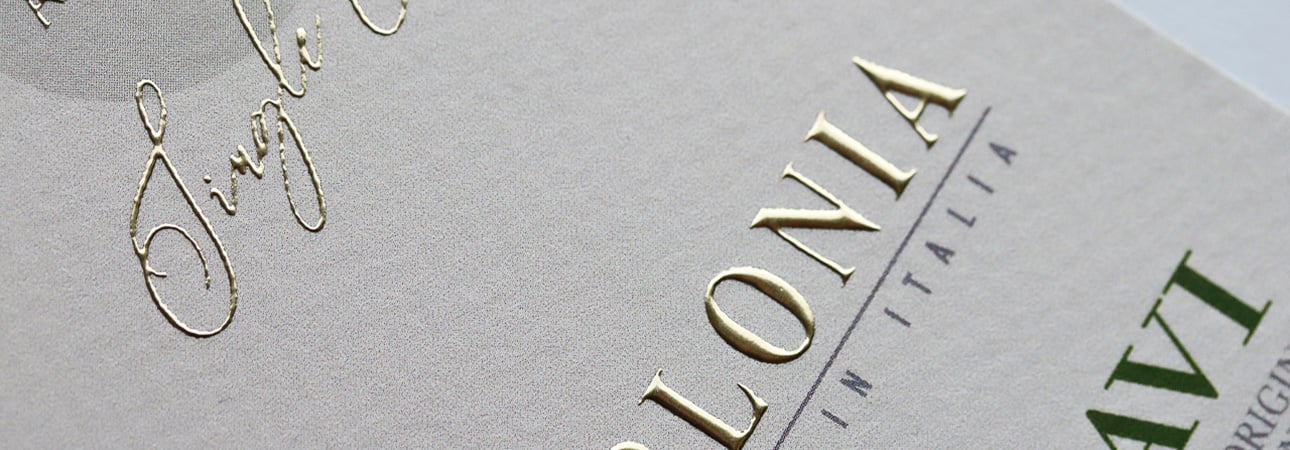

If you look very closely, have you ever seen a white space between two colours on a printed label? Or even between a colour and the hot foil?

If yes, Trapping is the solution for you. Trapping in printing is the compensation for misregistration between printing units on a multicolor press or even between a color and a particular finishing such as hot foil.

This misregistration causes gaps or white-space on the final printed label which look very awfull. Trapping files involves creating overlaps or underlaps of objects during prepress to fight misregistration on the press.

Why does it happen to my label?

As a paper reel runs through a printing press, being passed from unit to unit, it shifts. This movement usually is barely even measurable, often just a fraction of a millimeter, but the paper does move, especially when running through the press at high speed. This physical shift must be compensated when the art is being prepared in the prepress phase.

How can I solve it?

You don't have to deal with it!

Your printer partner for sure will use its experience to help you avoid this issue.

An expert printer always use in the prepress phase some graphic sofwares that can handle trapping. For example Esko has two trapping solutions: interactive trapping and automatic trapping, based on predefined settings.

A trap is an area of overlap between 2 colors caused by printing one color over the other along an adjoining edge. You have probably heard the terms CHOKE and SPREAD. A CHOKE is a trap that brings an outside color within the outline of a shape. A SPREAD is a trap that extends the shape outward into the outside color.

When deciding whether to trap or overprint, you need to know which color will be printed before the others.

When you check overprint, it means that this color will print over top of anything positioned below it. When you do not check overprint, it means that this item will drop out of anything positioned below it. This color will need trapping for sure.

Trapping amounts vary depending on the quality of the printing press, the substrate or paper stocks used and the speed of the printing press. The faster the speed the more chance of the inks falling out of registration with each other as the reel move through the press. It can be as thin as strokes 0.2 of a millimeter or as thick as 2 mm. Your printer will set their preferred trapping amounts based on the printing technique.

Although trapping is usually the domain of printers and prepress houses it is an important element for Graphic Designers to consider when designing printed material since it will change the colours of artwork if darker colours need to be overprinted on lighter colours or effects like white keyline strokes are needed to stop colors butting or trapping together.

Things you need to remember as a Graphic Designer

Darker colours hold their shape.

Light Colours spread under (choke) darker colours.

Spot PMS colours will always need trapping into Process CMYK colours.

Metallic Inks are opaque so all other inks will choke under them.

Special Consideration for Black

Black is the strongest ink and hides most of what it overprints. It is still a transparent ink and most process black ink is more dark brown than the rich dark black we love to see in our adhesive labels. If the size of the black type or graphic is large enough, you will be able to see the black colour shift as it overprints stronger or weaker colours under it. Graphic designers should pay attention to setting whether black type or graphics overprint the background, or knock out the background to print a consistent black colour.

100% Black over a color

Usually a 100% black placed over color need only be overprinted. 100% Black is opaque enough to cover whatever is under it.

Screened Black over a color

On the contrary screened black (a percentage of black) placed over a color is overprinted when you want to combine the colors. If you want the screened black to appear gray, it must be trapped. This means having a thin stroke of screened black above the color. The black part above the color does overprint the color itself. The rest of black is smaller and does not overprint. The result is an area of pure gray bounded by an area of combined black and color.

Percentage of color on a screened black

A color of any percentage placed over black of any percentage will have a similar scenario, but reversed. You need to overprint when you want to combine the colors. If you want the color to appear pure, it must be trapped. This means having a layer of color above the black. The overlapping part need to be overprinted whereas the rest does not overprint. The result is an area of pure color bounded by an area of combined black and color.

Ask For Help

Ask for help if you need any suggestion or advice! Our mission is to help businesses achieve bespoke custom labels for their brands that help them stand out.

Contact us, we are just a call away!

Next