Did you like the article? Share it!

How to define the size of an oil label in 4 simple steps!

How many times did it already happen to you to think about the design of an oil label and do not know where to start to define the size? In this short tutorial we will help you define the size of an oil label in 4 simple steps. Don't worry! A few simple steps will be enough to get the perfect size for your oil labels. Let's start!

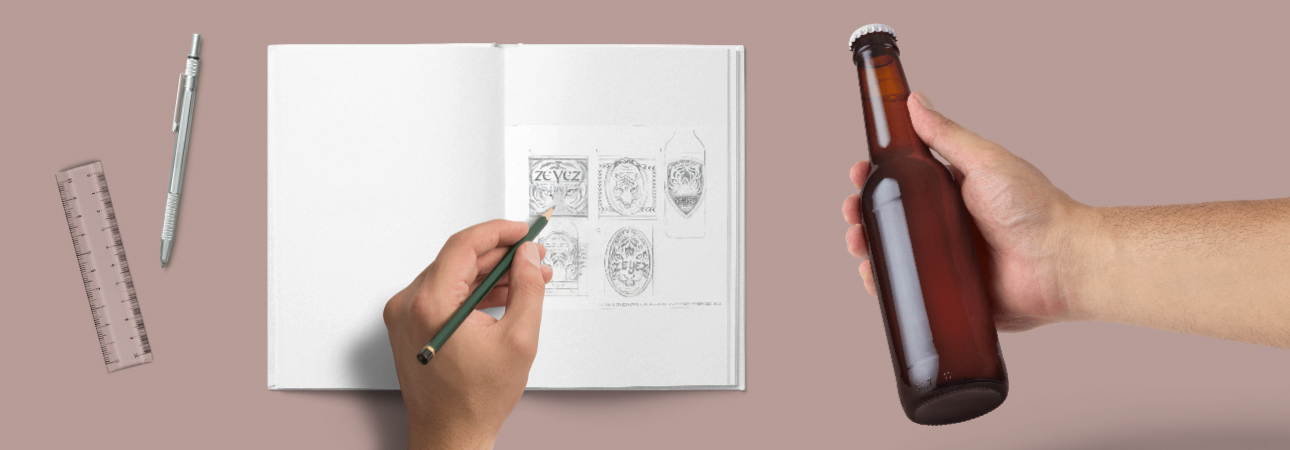

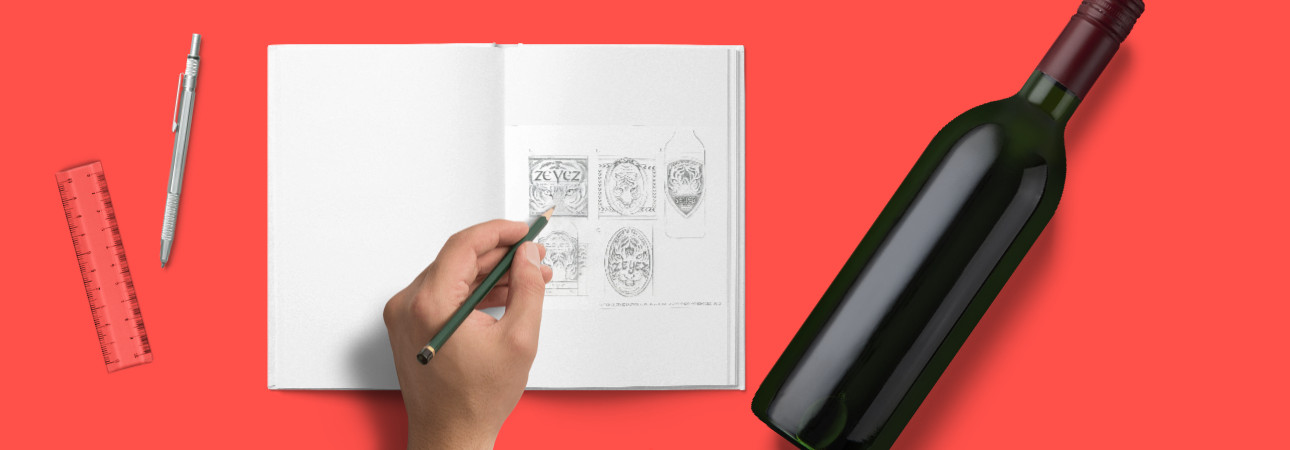

Tools of the trade

To accomplish this tough task, you will need some essential tools. First of all, you will need a flexible ruler, your faithful ally in defining the size of an oil label. You can download this valuable tool here. You will see that you will live without it anymore.

Then of course you will need the oil bottle that you need to dress up. Always keep it by your side both for the preliminary phase of defining the dimensions of your oil label and for testing.

Pen or pencil, faithful companion of the designer to "sketch" the first drafts. Graph paper or plain paper if you don't have it by your on hand. Obviously, the scissors to cut out the final "mockup" of the oil label. To get a professional proof or mockup, ask for our help.

Now that you have everything you need, we will show you 4 simple steps to get the perfect size for your oil label. Let's see them in detail.

1. Measurement phase of the oil bottle

To design the perfect size for a bottle of oil, you must first define the maximum size that the label could have depending on the shape of the bottle.

If the bottle is round, the flexible ruler can be used to measure the maximum width of the label. If you are thinking of a wrapping oil label, for example, which means a label that almost completely wraps the surface of the bottle, always remember to reduce the width by a few millimeters compared to the diameter of the bottle if you do not want the label to overlap on itself.

The square bottle is a bit simpler to define the size of the oil label. However, it is important to maintain certain proportions between the container and the label. Leave a few millimeters of bare bottle around the oil label. This will also greatly simplify the manual and automatic labelling phase.

2. Define the shape of the oil label

Once the overall dimensions of the oil label have been defined, it will be time to draw the die- cut path of the label. The die cut path determines the perimeter of the oil label on which the cut will be made during the production phase. To do this, use a graph paper on which you will write a rectangle with the maximum dimensions measured previously. If the oil label you imagined has a rectangular shape, your work is already done. On the contrary, if you imagined a personalized shape for the oil label, you can use this path to draw the correct shape. The graph sheet will be an excellent base to follow even if you have to draw curved shapes.

3. Cut the oil label

Is the die-cut path ready? All you have to do is cut the label obtained from the previous steps. The countdown has started and it's time to test the oil label on the bottle. This test allows you to make some adjustments on the size of the oil label in order to make it perfect.

Are you still not perfectly satisfied? No problem. Wrap or apply the label to the bottle and remove the excess as many times as you want. The flexible ruler will help you reduce the size of the oil label a few millimeters to do a perfect job.

4. Measure the final size of the oil label

The final step is to measure the result obtained. Spread the label on a flat surface and measure the base and the height of the label. Voilà… That's it!

Next